Startups

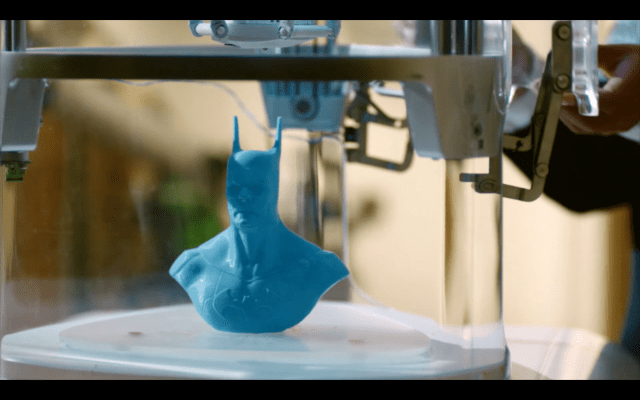

3DHubs, once a community 3D printing service, is now sourcing all 3D prints internally

3D Hubs, like MakeXYZ, was a community-based 3D printing service that let anyone with a printer sell their prints online. Founded in the heyday of the 3D printing revolution, the service let thousands of makers gather a little cash for making and mailing prints on their home 3D printers.

Now, however, the company has moved to a model in which its high-end partners will be manufacturing plastic, metal, and injection molded parts for customers willing to pay extra for a professional print.

“Indeed, more focus on high end printers run by professional companies,” said founder Brian Garret. “So a smaller pool of manufacturing locations (still hundreds around the world), but with more control on standardized quality and repeatability. Our software takes care of the sourcing, so companies order with 3D Hubs directly.”

Not everyone is happy with the decision. 3DPrint.come editor Joris Peels saw the value in a solid, dedicated community of hobbyists in the 3D space. The decision to move away from hobbyist printers, wrote Peels, “has confused many.”

“The value of 3DHubs is in its community; the community gives it granular local presence and a barrier to entry. Now it is just like any 3D printing service upstart and will lose its community entirely. I’ve always liked 3DHubs, although I have been very skeptical of their Trends Report I like the company and what they’re doing. I liked the idealism coupled with business,” he wrote.

The community, for its part, is angry.

The move will happen on October 1 when all prints will be completed by Fulfilled by 3D Hubs partners, dedicated merchants who will offer “source parts for larger, high value engineering projects.” The company wrote that during the early hobbyist days the “platform at that time was very much free-form, with the goal of serving as many, mostly one-off, custom maker projects as possible.”

This slow movement from hobbyist 3D printing to professional parts manufacturer is not surprising or unexpected, but it is jarring. The 3D printing community is small, vociferous, and dedicated to the technology. In the early days, when 3D printers were rare, it was tempting to buy a mid-price printer and become a small, one-person shop online. Now, with the availability of commodity printers that cost less than some paper printers, the novelty and utility of a low-resolution print has fallen considerably.

3D printing never fulfilled its promise in the home and small office. A one-off print can save some of us a trip to the machine shop or music store but in practice home 3D printing has been a bust.

Like most open source technologies that went commercial, the dedicated zealots will complain and the established players will pivot into profitability. It ruffles feathers, to be sure, but that’s how these things work. To paraphrase the White Stripes, “Well, you’re in your little room and you’re printing something good/ But if it’s really good, you’re gonna need a bigger room/ And when you’re in the bigger room, you might not know what to do/ You might have to think of how you got started sitting in your little room.”

-

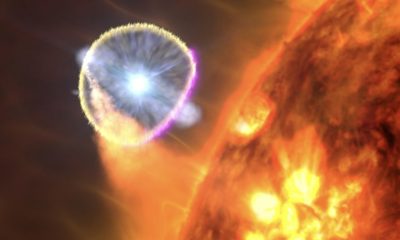

Entertainment7 days ago

Entertainment7 days agoThis nova is on the verge of exploding. You could see it any day now.

-

Business7 days ago

Business7 days agoIndia’s election overshadowed by the rise of online misinformation

-

Business6 days ago

Business6 days agoThis camera trades pictures for AI poetry

-

Business5 days ago

Business5 days agoTikTok Shop expands its secondhand luxury fashion offering to the UK

-

Business6 days ago

Business6 days agoBoston Dynamics unveils a new robot, controversy over MKBHD, and layoffs at Tesla

-

Business5 days ago

Business5 days agoMood.camera is an iOS app that feels like using a retro analog camera

-

Entertainment7 days ago

Entertainment7 days agoEarth will look wildly different in millions of years. Take a look.

-

Business4 days ago

Business4 days agoUnitedHealth says Change hackers stole health data on ‘substantial proportion of people in America’