Finance

LA-based sustainable fashion start-up turns milk into wearable fabric

As food waste becomes an increasingly prevalent issue, dairy waste is one that has been largely overlooked.

But an LA-based start-up is looking to solve the dairy waste problem by putting excess milk to good use.

Founded in late 2018, sustainable fashion start-up Mi Terro creates a positive environmental impact by making sustainable products with less-than-conventional materials — including ocean plastics and excess milk.

“Mi Terro is a green fashion brand that aims to solve world problems through means of sustainable fashion,” CEO and co-founder Robert Luo told Business Insider.

Their most recent product is the Milk Tee, which is produced with milk that would otherwise be dumped.

Luo said that he first became aware of dairy waste through videos on YouTube. He said he was both fascinated and astonished by the fact that 128 million tons of milk go to waste every year globally. Not only does excess dairy pose a problem in terms of food waste, it also raises concerns on how so much product can be sustainably discarded if not consumed.

A study conducted by the US Department of Agriculture estimated that dairy products make up approximately 17 percent of waste in landfills and incinerators, according to the International Dairy Foods Association.

The Indiana Department of Environmental Management classifies dairy waste as a product that does not “meet applicable quality standards, have become contaminated, or otherwise have become unusable for human consumption, animal feed, or any other beneficial use.”

“It’s a huge problem that nobody talks about,” Luo said.

Combining the newfound knowledge of dairy waste with his qualms about fast fashion, Luo said that he traveled the world for a year, contacting manufacturers and suppliers in China, where he is from, to find a solution to the two.

Eventually, he found and partnered with a Chinese manufacturer who up-cycled milk into fabric.

It can take up to two months to make the milk shirt.

Turning milk into a shirt isn’t an easy process, as one might expect. Luo said that it takes about two months to process dairy waste into a material that can be spun into a shirt.

Mi Terro begins the milk shirt-making process by sourcing excess milk from partnering dairy farms. From there, the milk is fermented and skimmed to remove the fat in the milk. The milk is then de-watered, forming a powdery substance. The milk powder is then dissolved once again to purify it and remove unwanted proteins, leaving resulting fibers that are stretched and spun into yarn.

To make a shirt out of the processed milk threads alone would make the shirt largely unaffordable, Luo said, so it is combined with micromodal — an organic material made of beech wood, similar to cotton but with more sustainable manufacturing. Each shirt is made up of about 15-20% milk, Luo said. According to the Mi Terro website, about 5 shirts equate one glass of milk.

Even though the Kickstarter campaign had an end date of Sept. 15 with a goal of $3,000, the shirt was fully funded in just two hours, Luo said. It has since gained over $26,000 from over 300 backers. The milk shirt now retails for $59 on the website.

The shirt is marketed as being odor-free, breathable, moisture wicking, stretching, and three times softer than cotton. Soft to the touch, the quality of the fabric feels luxurious, but the stretchiness of the shirt offers a versatility that is hard to come by in most high-end shirts.

Given the success of the Milk Tee campaign and the versatility of the lightweight milk-made fabric, Luo said the company is looking to make more products in the future, including socks, pajamas, scarves, and underwear.

Read more: 7 brands that make sustainable jeans using organic cotton and eco-friendly production methods

Mi Terro also sells tote bags made of natural cork and recycled ocean plastics.

Apart from posing a solution to dairy waste, Mi Terro expanded their environmental impact to the oceans. The first product the company developed is a weekender bag made of natural cork and plastic pulled from the ocean, which retails for $275. Luo said the name of the company, which roughly translates to “my earth” with language origins from Spanish and Portuguese, derives from this bag, since most cork is grown in Portugal and Spain.

Another extension of the company’s mission addresses the issue of deforestation through its partnership with the Eden Reforestation Project, a nonprofit that employs and offers fair wages to local impoverished villagers who work toward their mission of forest restoration. For every item sold, Luo said that 10 trees are planted. The company has planted 2,700 trees so far, Forbes reported.

“Many people are waiting for others to do something for environment, even though they [also] care about environmental protection and climate change … so I’m worried. I think everybody should be worried,” Luo said. “But we have to be really, really optimistic about the future, because we all have to work toward a positive direction.”

-

Business7 days ago

Business7 days agoLangdock raises $3M with General Catalyst to help businesses avoid vendor lock-in with LLMs

-

Entertainment7 days ago

Entertainment7 days agoWhat Robert Durst did: Everything to know ahead of ‘The Jinx: Part 2’

-

Entertainment6 days ago

Entertainment6 days agoThis nova is on the verge of exploding. You could see it any day now.

-

Business6 days ago

Business6 days agoIndia’s election overshadowed by the rise of online misinformation

-

Business6 days ago

Business6 days agoThis camera trades pictures for AI poetry

-

Business7 days ago

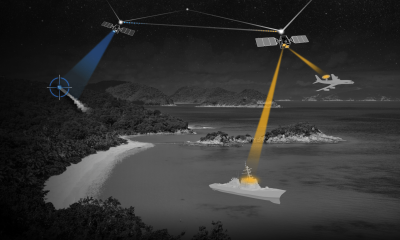

Business7 days agoCesiumAstro claims former exec spilled trade secrets to upstart competitor AnySignal

-

Business5 days ago

Business5 days agoTikTok Shop expands its secondhand luxury fashion offering to the UK

-

Business6 days ago

Business6 days agoBoston Dynamics unveils a new robot, controversy over MKBHD, and layoffs at Tesla