Finance

Air Force tests headset that uses wearer’s bones to transmit sounds

RAF MILDENHALL, England — An innovative in-ear headset is being tested by the 100th Aircraft Maintenance Squadron and 100th Maintenance Squadron at RAF Mildenhall, England.

The device, which uses the bones in the user’s ear to transmit sound waves, provides both communication and hearing preservation capabilities to airmen working in noisy environments.

RAF Mildenhall was awarded funding to test the product after US Air Forces in Europe and Air Forces Africa identified the base’s proposal, to incorporate bone conduction communication technology into their operations, as especially innovative. The base was paired with Denmark-based INVISIO, a hearing protection and communications company, which was able to supply a product using this technology.

“We’re funded by USAFE-AFAFRICA specifically to provide feedback and input to the Air Force on whether bone conduction is a viable option across many platforms,” explained US Air Force Master Sgt. Christopher Pettingill, 100th AMXS continuous process improvement and innovation manager. “We get to be the guinea pig and determine if it works for us and whether it’s worth investing in more.”

Maintenance airmen will be required to wear over the ear hearing protection in addition to the product, but they will more clearly be able to communicate due to the in-ear headset microphone.

“When aircraft engines are running or in a loud environment, our maintainers are required to wear ear plugs in addition to a headset,” said Pettingill. “Imagine sticking ear plugs in your ear and then trying to have a conversation with somebody; it doesn’t work. Enter the dual in-ear headset. This product offers hearing protection and also a microphone you can communicate with.”

In addition to enhancing hearing protection and communication abilities for maintainers, the device will also benefit airmen in other career fields during exercises and real-world conditions, circumstances which necessitate the wearing of protective gear.

“RAF Mildenhall wanted to invest in the product not only due to the advantages it would provide the maintenance squadron, but also the ease of communication it would provide users in an exercise or in a real world event,” said Pettingill. “If you’re wearing a gas mask and you are trying to communicate with a radio, it’s going to be muffled. The product provides a better alternative to radios, which you actually have to bring up to your face to speak into.”

The 100th AMXS and 100th MXS production staff were chosen to test the in-ear headset because they are responsible for the movement of manpower and resources on the flight line, including such things as where aircraft are parked, when fuel is dispatched and which maintainers service certain aircraft, responsibilities that make communication essential. They were given the opportunity to provide their feedback about what they liked and disliked about a device not initially designed for maintenance Airmen, but special operators.

“We’re afforded the resources and the money to provide that feedback,” said Pettingill. “It’s not all positive, but that should be expected. We’ll just have to make adjustments.”

Both maintenance squadrons continue to test the in-ear headsets they have, but they’re waiting for funding to become available that will allow them to purchase the bulk of the headsets for testing.

“Once we’re ready to execute, we will outfit our maintainers and encourage them to use the product as much as possible. We’re going for a single issue rollout, so each Airman will be assigned their own headset,” said Pettingill.

RAF Mildenhall’s position as the only installation in the Air Force to be testing this technology is due in large part to the maintenance senior leaders who were convinced of the product’s worthiness.

“It’s a huge honor to be able to test this innovative product,” remarked Pettingill. “We’re afforded the ability to try things out, and that’s why we are so successful. It doesn’t surprise me that we’re the first to do these things. Our leadership has our back.”

No federal endorsement is intended or implied of any private entities or their products.

-

Business7 days ago

Business7 days agoLangdock raises $3M with General Catalyst to help businesses avoid vendor lock-in with LLMs

-

Entertainment6 days ago

Entertainment6 days agoWhat Robert Durst did: Everything to know ahead of ‘The Jinx: Part 2’

-

Entertainment6 days ago

Entertainment6 days agoThis nova is on the verge of exploding. You could see it any day now.

-

Business6 days ago

Business6 days agoIndia’s election overshadowed by the rise of online misinformation

-

Business5 days ago

Business5 days agoThis camera trades pictures for AI poetry

-

Business6 days ago

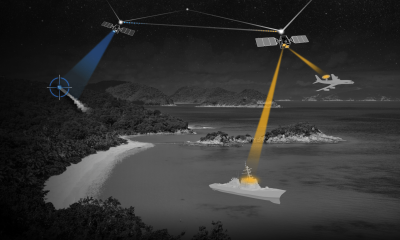

Business6 days agoCesiumAstro claims former exec spilled trade secrets to upstart competitor AnySignal

-

Business4 days ago

Business4 days agoTikTok Shop expands its secondhand luxury fashion offering to the UK

-

Business5 days ago

Business5 days agoBoston Dynamics unveils a new robot, controversy over MKBHD, and layoffs at Tesla