Technology

Tesla’s self-driving ‘brain’ hit with serious Trump administration tariff

Image: Artur Widak / NurPhoto / Getty

Tesla will have trouble innovating its way out of this one.

The car manufacturer is facing potentially serious financial headwinds in its attempt to equip all newly produced vehicles with the technology required to enable full self-driving. So reports TechCrunch, which notes that the White House won’t budge on a 25 percent tariff on the Chinese-assembled ‘engine control unit’ the cars require. Notably, this tariff wouldn’t apply to the entire car — just the ECU.

The so-called Autopilot ECU is assembled in Shanghai, and that irks the White House. Tesla officially requested a tariff exemption on the unit in question, but that request was denied on March 15. The rejection letter had not previously been reported before this week.

“[After] careful consideration, your request was denied because the request concerns a product strategically important or related to ‘Made in China 2025’ or other Chinese industrial programs,” reads the rejection letter signed by United States Trade Representative general counsel Stephen P. Vaughn.

The ‘Made in China 2025’ program, which the Wall Street Journal notes is no longer actually referred to by that name in China, is the country’s attempt to boost 10 specific economic sectors. It has frustrated US officials, whom the Journal reports call it a subsidy program.

So what does that mean for Tesla — both the company and customers hoping to embrace the self-driving future? Likely a more expensive ride, for one thing.

“This module is the brain of the vehicle,” Tesla wrote in its now-rejected application for tariff exemption. “The imposed tariffs are forcing us to either source a new supplier, pass the cost increase to the end customer, or reduce operational costs within our internal operations, all having a reverse impact for what it believes to be the intention of the tariff.”

According to Tesla, a new supplier is essentially out of the question.

“For a product as safety critical to consumers, and critical to the essence of Tesla, we turned to industry experts who could achieve this quality and complexity in addition to the deadlines, which was not possible outside of China,” the company wrote in the aforementioned application. “Choosing any other supplier would have delayed the program by 18 months with clean room setup, line validation, and staff training.”

In other words, it looks like the production — and cost — of self-driving Teslas is about to get a even pricier.

-

Business6 days ago

Business6 days agoTesla’s new growth plan is centered around mysterious cheaper models

-

Business5 days ago

Business5 days agoXaira, an AI drug discovery startup, launches with a massive $1B, says it’s ‘ready’ to start developing drugs

-

Business6 days ago

Business6 days agoUK probes Amazon and Microsoft over AI partnerships with Mistral, Anthropic, and Inflection

-

Entertainment4 days ago

Entertainment4 days agoSummer Movie Preview: From ‘Alien’ and ‘Furiosa’ to ‘Deadpool and Wolverine’

-

Business5 days ago

Business5 days agoPetlibro’s new smart refrigerated wet food feeder is what your cat deserves

-

Business3 days ago

Business3 days agoHow Rubrik’s IPO paid off big for Greylock VC Asheem Chandna

-

Entertainment3 days ago

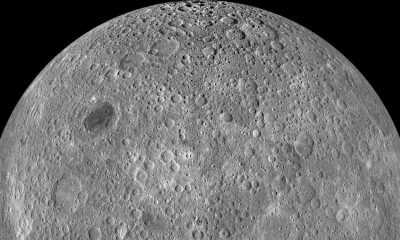

Entertainment3 days agoWhat’s on the far side of the moon? Not darkness.

-

Business4 days ago

Business4 days agoThoma Bravo to take UK cybersecurity company Darktrace private in $5B deal